Our cylinders are durable and designed, manufactured and tested for each individual project.

From standard cylinders to special cylinders, from one-offs to series production, with our decades of experience, we understand and meet the requirements in your project.

Telescopic cylinders, synchronous cylinders, lightweight cylinders, water-cooled, with mounted superstructures, on/off shore cylinders, ATEX versions or special cylinders. Our cylinders are extremely varied, see for yourself:

We are one of the leading partners for numerous industrial sectors and a wide range of applications when it comes to the production of custom-made hydraulic cylinders. This is where we demonstrate our comprehensive core competence: from standard (ISO) cylinders to special cylinders with various applications, telescopic cylinders and oscillating cylinders, HAINZL is a household name for customers worldwide. There are virtually no limits to the size, dimensions, design and equipment.

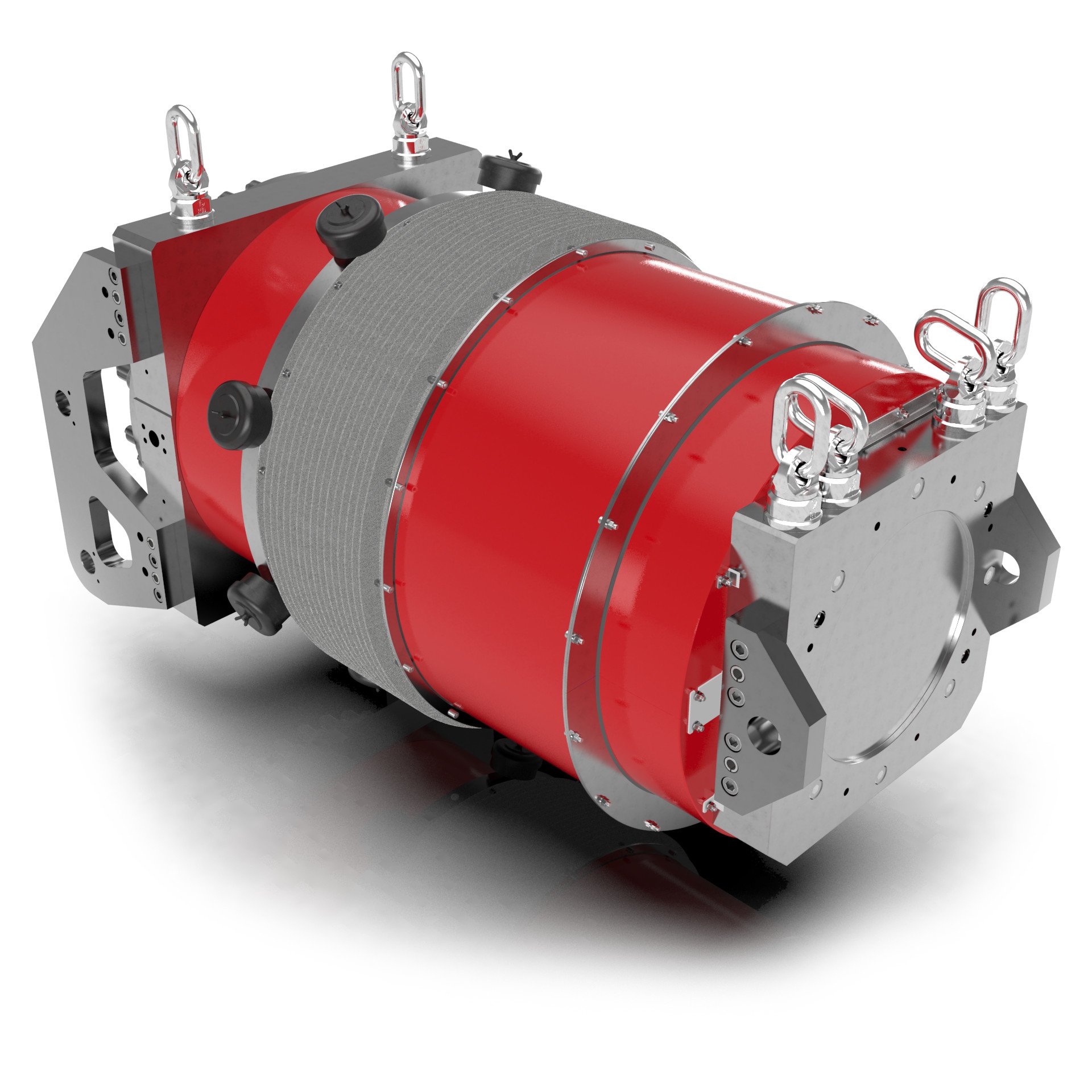

Our heavyweights and endurance runners for industry, heavy mechanical engineering or power plants.

We individually equip your cylinder with displacement measuring systems, water cooling, mounted rotary unions, mechanical interlocks or many other options.

// Piston diameter: up to 1.000 mm

// Stroke lengths: up to 10.000 mm

// Nominal pressure: up to 700 bar

// Weight: up to 25 t

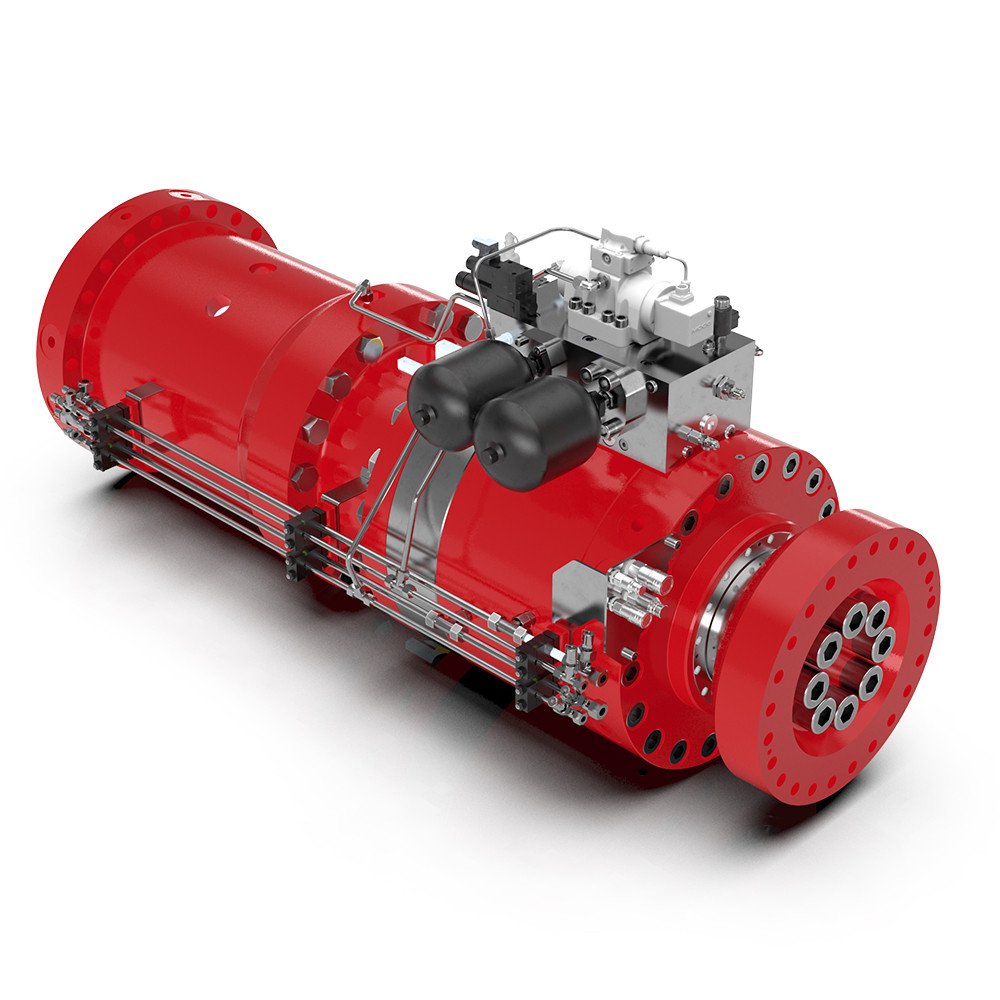

Our cylinders developed for steel hydraulic engineering are individually designed and manufactured in compliance with the strictest applicable standard DIN 19704.

The multitude of design variants ranges from stainless steel piston rods, mechanical or hydraulic locking, special coatings to seawater-resistant design.

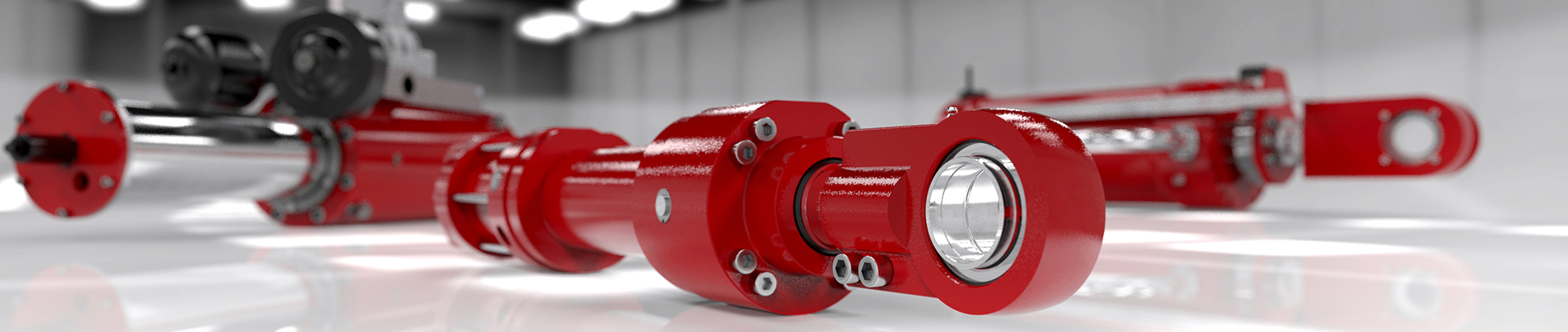

Our servo-hydraulic cylinders are used wherever maximum accuracy, dynamics, frequency and lateral load capacity are required.

They have proven their precision for years in mechanical engineering, test bench construction and in the steel processing industry.

We offer our self-developed and high-quality produced servo-hydraulic cylinders for linear motion in three series: Oscillating cylinders, annular gap cylinders and hydrostatic cylinders.

// Servo-hydraulic axis (very easy to maintain, seal-less)

// Hydrostatic bearing

// Cylinder with annular gap seal (low maintenance)

// Minimal wear

// High load capacity

// No stick slip effect

// High static stiffness and high damping

Our standard cylinders are used worldwide because the mounting dimensions, installation lengths, piston rod ends and connecting threads are standardized globally.

Our standard cylinders according to ISO 6020/2 and ISO 6022 cover the pressure range from 160 to 250 bar.

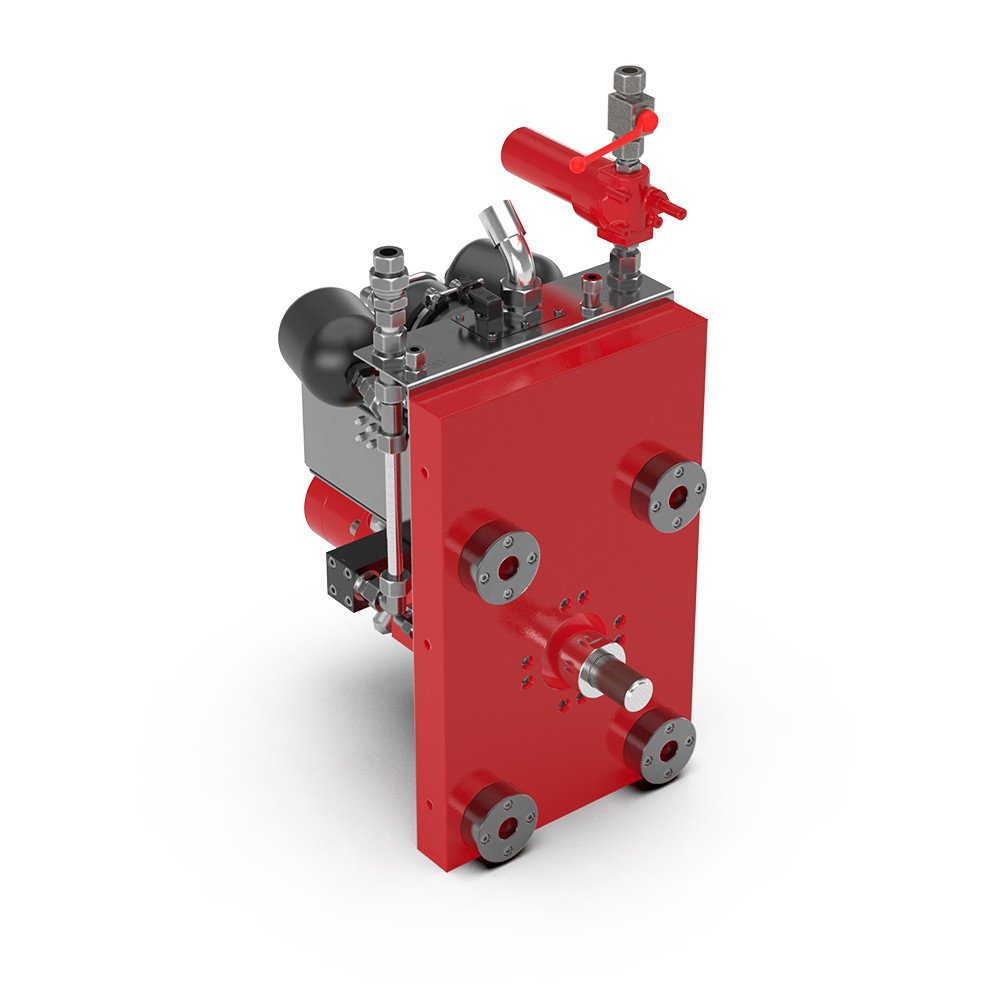

Our special cylinders represent our competence and experience in cylinder construction from more than 55 years.

We produce these cylinders in a wide variety of customized designs with our extensive application and industry knowledge.

// Almost no limits in dimension and design

// Strength lies in customized design

// Own mechanical

// Multiple cylinder

// Water cooled cylinder

// Explosion proof cylinder (ATEX)

// ON/OFF Shore cylinder

Our telescopic cylinders consist of several cylinders built into each other. With relatively small installation lengths, they can thus generate large strokes.

In addition, we integrate individual attachments and superstructures into your cylinder.

// Up to 4 stages

// Pressure stages up to 500bar

We extend the service life and safety of your cylinders through comprehensive repair and maintenance. We support you with maintenance work and a smooth process by carrying out an expert inventory and analysis so that the cylinder is quickly available for your production again.

1200

mm piston diameter

12

m stroke length

25

tonnes max. weight

700

bar nominal pressure

As a manufacturer of high-quality hydraulic cylinders, we are known to customers all over the world - and have been since 1965. Our cylinders are durable and robust and have been doing their job reliably for decades.